The closest materials to advanced ceramics are high-performance engineering materials, particularly those with high hardness, high wear resistance, high-temperature resistance, and excellent chemical stability. Below are several types of materials that are most similar to advanced ceramics in terms of performance:

1. Carbon Fiber Composites

Carbon fiber composites are materials composed of carbon fibers reinforced with a polymer matrix (such as epoxy resin), offering lightweight, high strength, and high-temperature resistance.

- Similarities:

- High specific strength and specific modulus.

- Excellent high-temperature performance (some carbon fiber composites can be used at high temperatures).

- Good chemical stability.

- Applications: Aerospace, automotive, sports equipment, industrial machinery.

- Differences: Carbon fiber composites are generally lighter than ceramics but have lower hardness and wear resistance.

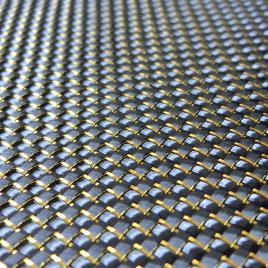

2. Metal Matrix Composites (MMCs)

Metal matrix composites are materials formed by combining ceramic particles or fibers (such as silicon carbide or alumina) with a metal matrix (such as aluminum, magnesium, or titanium).

- Similarities:

- High hardness and wear resistance.

- Good thermal conductivity and high-temperature performance.

- Excellent mechanical properties (strength, toughness).

- Applications: Aerospace, automotive, electronic packaging, thermal management.

- Differences: Metal matrix composites have higher toughness and conductivity than ceramics but may have poorer corrosion resistance.

3. Superhard Materials

Superhard materials are a class of materials with hardness close to or exceeding that of diamond, such as cubic boron nitride (cBN) and polycrystalline diamond (PCD).

- Similarities:

- Extremely high hardness and wear resistance.

- Excellent high-temperature performance.

- Chemical inertness (e.g., cBN does not react with ferrous metals at high temperatures).

- Applications: Cutting tools, abrasives, wear-resistant coatings.

- Differences: Superhard materials are typically more expensive than ceramics and more difficult to process.

4. Superalloys

Superalloys are a class of metallic materials that maintain excellent performance under extreme temperatures and stress conditions, such as nickel-based, cobalt-based, and iron-based alloys.

- Similarities:

- Excellent high-temperature performance (usable above 1000°C).

- Good oxidation and corrosion resistance.

- High strength and creep resistance.

- Applications: Aircraft engines, gas turbines, nuclear reactors.

- Differences: Superalloys are heavier than ceramics but offer better toughness and impact resistance.

5. Glass-Ceramics

Glass-ceramics are materials produced through controlled crystallization, combining the properties of glass and ceramics.

- Similarities:

- High hardness and wear resistance.

- Excellent thermal and chemical stability.

- Tunable thermal expansion coefficient.

- Applications: Cookware, optical devices, biomedical materials.

- Differences: Glass-ceramics generally have lower mechanical properties than advanced ceramics but offer better optical transparency.

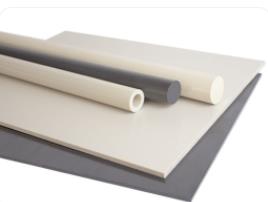

6. High-Performance Polymers

Certain high-performance polymers, such as polyetheretherketone (PEEK) and polyimide (PI), exhibit excellent heat resistance, chemical stability, and mechanical properties.

- Similarities:

- Good high-temperature performance (some polymers can be used above 250°C).

- Excellent chemical stability and wear resistance.

- Lightweight and high strength.

- Applications: Aerospace, automotive, electronics, medical.

- Differences: Polymers generally have lower hardness and wear resistance than ceramics but offer better toughness and processability.

7. Graphite and Graphene-Based Materials

Graphite and graphene-based materials have unique layered structures, exhibiting excellent thermal conductivity, electrical conductivity, and mechanical properties.

- Similarities:

- High thermal conductivity and high-temperature performance.

- Good chemical stability.

- Lightweight and high strength.

- Applications: Thermal management, electronic devices, composites.

- Differences: Graphite and graphene materials have lower hardness but possess unique electrical and thermal properties.

Comparison table:

Here’s a comparison table summarizing the key properties and applications of advanced ceramics and the closest non-ceramic materials:

| Material | Key Properties | Advantages Over Ceramics | Limitations Compared to Ceramics | Applications |

|---|---|---|---|---|

| Advanced Ceramics | High hardness, wear resistance, high-temperature stability, chemical inertness. | Excellent mechanical and thermal properties. | Brittle, difficult to machine, high cost. | Aerospace, medical, electronics, industrial. |

| Carbon Fiber Composites | Lightweight, high strength, high-temperature resistance, chemical stability. | Lighter, better toughness, easier to shape. | Lower hardness and wear resistance. | Aerospace, automotive, sports equipment. |

| Metal Matrix Composites | High hardness, wear resistance, thermal conductivity, toughness. | Better toughness, higher thermal/electrical conductivity. | Heavier, may have lower corrosion resistance. | Aerospace, automotive, electronic packaging. |

| Superhard Materials | Extreme hardness, wear resistance, thermal stability, chemical inertness. | Harder than most ceramics, excellent wear resistance. | Very expensive, difficult to process. | Cutting tools, abrasives, wear-resistant coatings. |

| Superalloys | High-temperature strength, oxidation resistance, creep resistance. | Better toughness, higher ductility. | Heavier, lower hardness and wear resistance. | Aircraft engines, gas turbines, nuclear reactors. |

| Glass-Ceramics | High hardness, thermal stability, chemical resistance, optical transparency. | Better optical properties, tunable thermal expansion. | Lower mechanical strength. | Cookware, optical devices, biomedical materials. |

| High-Performance Polymers | Lightweight, chemical resistance, thermal stability, toughness. | Better toughness, easier to process. | Lower hardness, limited high-temperature use. | Aerospace, automotive, electronics, medical. |

| Graphite/Graphene Materials | High thermal/electrical conductivity, lightweight, chemical stability. | Excellent thermal/electrical properties, lightweight. | Lower hardness, anisotropic properties. | Thermal management, electronics, composites. |

Conclusion

Advanced ceramics are a class of high-performance materials known for their exceptional hardness, wear resistance, thermal stability, and chemical inertness. These properties make them indispensable in demanding applications across industries such as aerospace, medical, electronics, and industrial manufacturing. However, their brittleness, high cost, and machining difficulties often limit their use in certain scenarios.

To address these limitations, several non-ceramic materials offer complementary properties and can serve as alternatives or supplements to advanced ceramics. These include:

- Carbon Fiber Composites: Lightweight and tough, ideal for applications requiring high strength-to-weight ratios.

- Metal Matrix Composites: Combine toughness and thermal conductivity, suitable for structural and thermal management applications.

- Superhard Materials: Excel in extreme hardness and wear resistance, though they are costly and difficult to process.

- Superalloys: Provide excellent high-temperature performance and toughness, commonly used in aerospace and energy sectors.

- Glass-Ceramics: Offer a balance of hardness, thermal stability, and optical transparency, useful in cookware and biomedical devices.

- High-Performance Polymers: Lightweight and easy to process, with good chemical and thermal resistance, though limited in high-temperature applications.

- Graphite/Graphene Materials: Unique thermal and electrical properties, ideal for thermal management and electronic applications.

Key Considerations for Material Selection

- Mechanical Properties: For high hardness and wear resistance, advanced ceramics or superhard materials are preferred. For toughness, metal matrix composites or superalloys are better choices.

- Thermal Properties: Advanced ceramics and superalloys excel in high-temperature environments, while graphite/graphene materials are ideal for thermal management.

- Weight: Carbon fiber composites and high-performance polymers are the best options for lightweight applications.

- Cost and Processability: High-performance polymers and metal matrix composites are often more cost-effective and easier to process than advanced ceramics.

Final Thoughts

The choice between advanced ceramics and their alternatives depends on the specific requirements of the application, including mechanical, thermal, electrical, and environmental factors. By leveraging the unique strengths of each material, engineers and designers can optimize performance, reduce costs, and overcome the limitations of advanced ceramics in various industries. Continued research and innovation in material science will further expand the possibilities for these high-performance materials, enabling new applications and technological advancements.