The article details the application of ultra-precision polishing technology, specifically shear thickening polishing (STP), to difficult-to-machine materials, with a focus on silicon nitride (Si3N4) ceramics. It explores the limitations of existing polishing techniques, introduces STP, and presents a study on the use of a novel diamond-based shear-thickening polishing slurry (STPS) for achieving high-efficiency and high-precision polishing of Si3N4 ceramic which is one of advanced ceramics.

Introduction:

The demand for ultra-smooth surfaces on difficult-to-machine materials has driven significant advancements in ultra-precision polishing techniques. Methods like magnetorheological finishing (MRF), electrorheological mechanical polishing (EFP), and chemical mechanical polishing (CMP) have become crucial for achieving this goal . However, each method presents its own challenges. MRF and EFP suffer from the high cost of MR and ER fluids, respectively . CMP, while effective at removing material at the nanoscale, raises environmental concerns due to the chemical nature of the polishing slurries . These limitations have spurred research into alternative polishing methods that are efficient, cost-effective, and environmentally friendly. Shear thickening polishing (STP) has emerged as a promising candidate .

What are Shear-Thickening Fluids (STFs)?

Imagine a fluid that acts like a liquid when you stir it slowly, but becomes thicker and more resistant when you stir it quickly. That’s essentially how an STF behaves. These fluids are typically composed of tiny particles suspended in a liquid. When a low shear force is applied, they flow freely. However, when the shear force increases (like during the polishing process), the particles clump together, causing the fluid’s viscosity to increase dramatically.

How does STP work for Si3N4 ceramics?

- STF Slurry: An STF is prepared with abrasive particles (like diamond) dispersed within it. This slurry is used as the polishing medium.

- Controlled Shear: During polishing, the STF is subjected to controlled shear forces. This can be achieved through the movement of the polishing tool or the workpiece.

- Selective Polishing: In areas where the shear force is higher (e.g., where there are surface irregularities or bumps), the STF thickens, increasing the polishing pressure and material removal rate. Conversely, in smoother areas where the shear force is lower, the STF remains more fluid, resulting in less aggressive polishing.

- Ultra-Precision: This self-regulating mechanism allows for very precise material removal, leading to extremely smooth and damage-free surfaces on the Si3N4 ceramic.

Shear Thickening Polishing (STP): A Novel Approach:

STP utilizes a non-Newtonian fluid polishing slurry that exhibits shear thickening behavior. This fluid, known as a shear thickening fluid (STF), remains in a liquid state under normal conditions but transforms into a rigid, solid-like state when subjected to shear stress or impact. This unique characteristic has found applications in various fields, including damping systems, liquid body armor (Kevlar), and protective gear . The application of STF-based polishing slurries (STPS) for precision polishing of materials, however, is a relatively new area of research.

Challenges and Opportunities with Si3N4:

Silicon nitride (Si3N4) ceramics possess exceptional properties, including high hardness, high rigidity, wear resistance, low density, and chemical inertness. These characteristics make Si3N4 an ideal material for high-performance components like bearing rolling elements. However, these same properties also make Si3N4 challenging to machine . While previous work, such as that by Li Min et al. [9], has explored STP of Si3N4 using cubic boron nitride (CBN) abrasive-based STPS, achieving surface roughness (Ra) values in the range of 7.2 nm to 9.6 nm after 150 minutes, these studies did not address crucial aspects like roundness error and overall processing accuracy. Furthermore, the rheological properties of the STPS, which directly influence surface quality and polishing efficiency, require detailed investigation.

Research Objectives and Approach:

This research focuses on developing a novel diamond-based STPS and evaluating its performance in the ultra-precision polishing of Si3N4. The study aims to:

- Prepare a diamond-based STPS using diamond abrasive grains, an STF base liquid containing shear-thickening phase particles, and deionized water.

- Conduct STP experiments on Si3N4 workpieces using the developed STPS.

- Investigate the rheological behavior of the diamond-based STPS, including its viscosity, shear stress relationship, storage modulus (G’), loss modulus (G”), and loss factor (tan δ or η’).

- Analyze the surface quality of the Si3N4 workpieces after STP, including surface roughness (Ra) and surface morphology.

- Evaluate the material removal rate (MRR) during the STP process.

- Assess the roundness error of Si3N4 cylindrical workpieces before and after STP.

By combining experimental work with detailed analysis of the STPS rheology and the resulting workpiece surface characteristics, this research aims to establish a foundation for the practical implementation of high-efficiency and high-precision STP technology for Si3N4 ceramic components. The goal is to overcome the limitations of existing polishing methods and provide a more sustainable and cost-effective solution for achieving ultra-smooth surface finishes on this challenging material.

Detailed Explanation of Key Concepts and Equations:

-

Shear Thickening Fluid (STF): A non-Newtonian fluid whose viscosity increases with increasing shear rate. This behavior is crucial for STP, as it allows the STPS to behave like a liquid during initial contact with the workpiece but become more rigid under the shear forces generated during polishing, enhancing material removal.

-

Rheology: The study of the deformation and flow of matter. Understanding the rheological properties of the STPS is essential for optimizing the STP process.

-

Preston Equation: An empirical equation used to model material removal rate (MRR) in polishing. The basic form is:

MRR = kpv

Where:

- MRR is the material removal rate.

- k is the Preston coefficient (a constant).

- p is the pressure applied to the workpiece surface.

- v is the relative velocity between the polishing tool and the workpiece.

This equation is often modified to account for factors like abrasive grain size and material hardness.

-

Non-Newtonian Power-Law Fluid: A fluid whose viscosity is not constant but varies with shear rate. STFs typically follow a power-law relationship:

τ = Kγ̇ⁿ

Where:

- τ is the shear stress.

- K is the consistency index.

- γ̇ is the shear rate.

- n is the flow behavior index. For shear-thickening fluids, n > 1.

-

Storage Modulus (G’): A measure of the elastic energy stored in the material during deformation.

-

Loss Modulus (G”): A measure of the viscous energy dissipated in the material during deformation.

-

Loss Factor (tan δ or η’): The ratio of the loss modulus to the storage modulus (G”/G’). It indicates the balance between the viscous and elastic behavior of the material.

This detailed explanation provides a more comprehensive understanding of the background, objectives, and key concepts involved in this research on shear thickening polishing of Si3N4. It sets the stage for a deeper dive into the experimental methodology, results, and discussion in the subsequent sections of the document.

Conclusion:

The conclusions of the research on shear thickening polishing (STP) of Si3N4 using a diamond-based polishing slurry (STPS) can be summarized as follows:

-

Rheological Characterization: The diamond-based STPS exhibited non-Newtonian, power-law fluid behavior with shear-thickening characteristics. It demonstrated shear thinning at low shear rates followed by a reversible shear-thickening effect at higher shear rates. The storage modulus (G’), loss modulus (G”), and loss factor (η’) of the STPS were found to vary with shear rate, providing valuable insights into its viscoelastic behavior during the polishing process. The formation and breakdown of diamond “particle clusters” within the STPS were observed and linked to the shear thickening mechanism, which is crucial for achieving the desired polishing action.

-

Polishing Performance: The STP process using the diamond-based STPS proved to be an effective method for polishing Si3N4 ceramics. The material removal rate (MRR) was influenced by the diamond abrasive grain size, with the 0.2 μm grain size exhibiting a relatively higher MRR. The agreement between the theoretical and experimental MRR values, with an average error of approximately 11.7%, validated the applicability of the STP material removal model in the polishing zone.

-

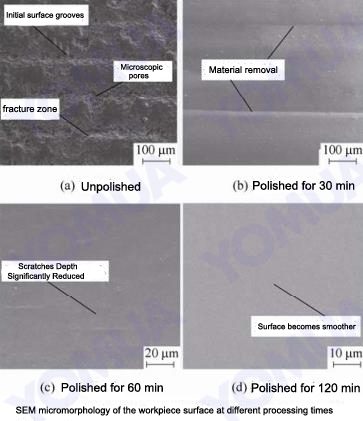

Surface Quality Improvement: Significant improvements in surface roughness (Ra) were achieved through STP. After 60 minutes of polishing with the 0.2 μm diamond STPS, the Ra value decreased from 107.2 nm to 26.5 nm. Further polishing to 120 minutes resulted in an Ra value of 6.5 nm, demonstrating the potential of STP for achieving ultra-smooth surface finishes on Si3N4.

-

Roundness Error Reduction: STP also effectively reduced the roundness error (RONt) of Si3N4 cylindrical workpieces. The RONt value decreased from an initial 1.418 μm to 0.360 μm after 120 minutes of polishing, highlighting the potential of this technique for improving the dimensional accuracy of Si3N4 components.

-

Overall Advantages: The diamond-based STPS demonstrated considerable potential for enhancing the efficiency and surface quality (including roughness and roundness) of Si3N4 STP. The combination of the shear-thickening behavior of the STPS with the controlled material removal by the diamond abrasives offered a promising approach for high-precision polishing of this challenging material. The developed STPS offers advantages over traditional polishing methods by providing a more efficient, potentially lower-cost, and environmentally conscious approach for achieving ultra-smooth surfaces on Si3N4.